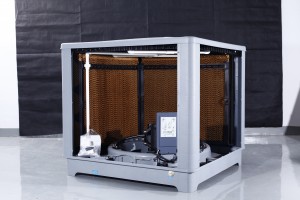

1. Look at the appearance of water air cooler. The smoother and more beautiful the product is, the higher the precision of the mold used. Although a good-looking product is not necessarily high-quality, a high-quality product must be good-looking. Therefore, when purchasing, we can touch the shell of the device with our hands to see if there are scratches, uneven surface, deformation, etc.; or if there is uneven distribution of pigments, spots, aerosols, bubbles and other defects; In addition to the plastic shell, stainless steel is also one of the excellent materials. In today’s business environment, a product that is unwilling to pay attention to its appearance can never be made into a product with guaranteed quality.

2. Look at the craftsmanship of water air cooler. The reason why German machinery and equipment is famous all over the world is precisely because of its sophisticated production technology. The production and processing technology is not only directly reflected in the operation status of the product, but also shows the working attitude and style of an enterprise, and the advanced level of equipment. When purchasing products, readers can check whether the joints are tightly connected, whether the screws, buttons and other small parts used are delicately made, whether the installation is tight, whether the contact is good, and so on. If there are problems with even these minimum components, then the quality of key internal components can be imagined.

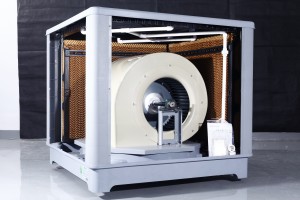

3. Look at the parts of water air cooler. The whole machine is composed of various parts and components, and the quality of the parts is directly related to the service life and effect of the equipment. Therefore, looking at the main accessories is the most important part of the whole selection process. The main components of evaporative refrigeration and air conditioning are: main control box, drain valve, water pump motor, fan.

The main control box is equipped with a control circuit board, which is the control system for the entire air conditioner operation. All indicators to ensure the normal operation of the air conditioner are adjusted here. Therefore, whether the circuit board design is reasonable or not, and the quality of the components used will affect the effect of its operation. However, it is difficult for ordinary consumers to accurately identify this. When choosing, you can ask the salesperson about the brand of each component inside the product.

The blowdown valve is a key component of evaporative refrigeration and air conditioning. Since this kind of air conditioner does not use refrigerant, it is pumped out by the uninterrupted water in the circulating water pump, and evenly sprayed on the filter layer through the water distribution system, the outdoor air enters the evaporative cooling medium CELDEK and fully exchanges heat with water, because The cool and clean air cooled by the evaporation of water is sent into the room by the low noise fan. The function of the blowdown valve is to filter and purify the impurities in the circulating water to ensure the effect. Now, high-end blowdown valves have built-in high-precision electromagnetic components with high sensitivity.

The pump motor and fan are the driving force of the whole system. For the motor of evaporative refrigeration and air-conditioning, the most important thing is to have a good moisture-proof effect; general low-quality motors are prone to leakage, rust, etc., and in serious cases, the motor may be burned out due to water ingress. In addition, the work efficiency of the motor is also an important aspect of the evaluation. The motor ratio of each machine must be reasonable, otherwise it will affect the work efficiency.

Post time: May-23-2022