Many iron sheet factory enterprises face the heat problem. Due to the poor thermal insulation performance of the iron sheet, heat is easy to penetrate the iron tile roof when the sun is shining, causing the temperature in the factory building to continue to rise. In addition, the mechanical equipment in the iron sheet factory building generate heat constantly during work, resulting in continuous high temperature and stuffy heat in the iron sheet factory building. If we choose ordinary traditional air conditioners to cool down the temperature, the electricity cost will be very high. So how to cool the iron sheet factory, so as to achieve the desired result and save money at the same time?

1. The overall cooling scheme of the iron sheet workshop

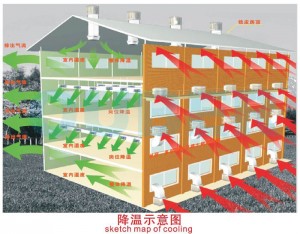

The cooling of iron sheet workshops basically use environmentally friendly evaporative air cooler. The overall cooling scheme of evaporaitve air cooler is suitable for cooling and ventilation of workshops with specific requirements for factory temperature and crowed workers. The overall cooling scheme can quickly reduce the temperature of the entire factory by about 5-10 degrees, continuously exhausting the stuffy air out of workshop, and cooling down the room at the same time, adding oxygen content.

2. Cooling and ventilation scheme for local posts

Many iron sheet factories are in the state of half warehouse and half workshop, and the places where workers have fixed areas. This situation is very suitable for position cooling solutions. In the place where people work, use the air supply duct connect air cooler and open the air outlet on it to cool down the fixed post. The partial position cooling and ventilation scheme is an economical and practical cooling scheme for iron sheet factory buildings, which can solve the problem of bringing cool and fresh air to workers, and can also control the cost . it is very popular for many factories.

Post time: Apr-07-2023