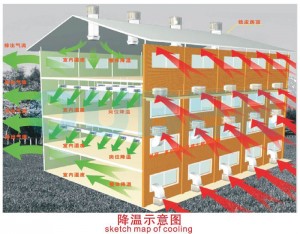

Industrial evaporative air cooler system can solve ventilation, cooling, oxygenation, dust removal, odor removal, and reduce the harm of toxic and harmful gases to the human body at one time for factories . So many benefits the air cooler bring , how to install the cooler machine? Following details of the installation methods and installation effect diagrams of industrial air cooler in different plant environments to your reference.

Technical requirements for environment friendly air conditioner installed on the external wall:

A 40*40*4 angle iron frame is used to connect the wall or window plate bolts, and the air duct and the angle iron frame are cushioned with rubber to prevent vibration, and all gaps are sealed with glass or cement mortar. The air supply elbow should be done according to the requirements of the drawings, and the cross-sectional area should not be less than 0.45 square meters. When installing the air duct, install a boom on the installation base frame so that all the air duct weight is hoisted on the base frame.

1. The welding and installation of the triangle bracket should be firm;

2. The overhaul platform must be able to support the weight of the crew and maintenance personnel;

3. The host installation must be level;

4. The section of the main engine flange and the air supply elbow must be flush;

5. All external wall ducts must be waterproofed;

6. The mainframe junction box must be installed by the temple for easy maintenance;

7. A waterproof bend should be made at the elbow of the air duct to prevent water from flowing into the room.

Technical requirements for tin tile roof installation methods:

1. The roof truss must have enough strength to bear the weight of the crew and maintenance personnel;

2. The roof opening size should not be greater than the installation size of the air duct 20mm;

3. The installation must be level;

4. The section of the main engine flange and the air supply elbow must be flush;

5. All zinc iron tile ducts must be waterproofed;

6. Support frames must be added to the four corners.

The technical requirements for the installation method of the roof of the brick wall structure factory building:

1. The 40*40*4 angle iron frame is connected and fixed with reinforced concrete bolts; 2. The roof frame must have sufficient strength to bear the weight of the unit and maintenance personnel; 3. The roof opening size should not be greater than the installation size of the air duct 20mm; 4. The installation must be level; 5. The section of the main engine flange and the air supply elbow must be flush; 6. All roof air pipes must be waterproofed; 7. Support frames must be added to the four corners.

If you encounter some factors that are not conducive to supporting air duct engineering during the installation process, Please take precautions when opening holes (wall holes, glass openings, and iron sheet openings). Water seepage repair work, so as not to allow enterprises to encounter roof leakage and other phenomena in the later period, causing damage to the workshop wall or direct water leakage affecting normal production in the workshop.

Post time: Nov-26-2021